How Aerobarrier air sealing Works

AeroBarrier makes it possible to easily meet or exceed the envelope sealing requirements of ENERGY STAR®,LEED, or Net Zero more consistently and cost-effectively than traditional methods.

AeroBarrier is an interior applied air sealing system that seals all building envelope leaks up to 1/2″. The waterborne acrylic sealant is applied by pressuring a targeted building area, then spraying the aerosolized sealant into the pressurized space.

The sealant is self-guided to the edges of visible and invisible leaks creating a seal, not by packing the gap, but by accumulating across the surface of leaks. The sealant is applied within 60-90 minutes and dries before system clean up is complete allowing construction to resume shortly after the process is complete with little to no impact on standard construction schedules.

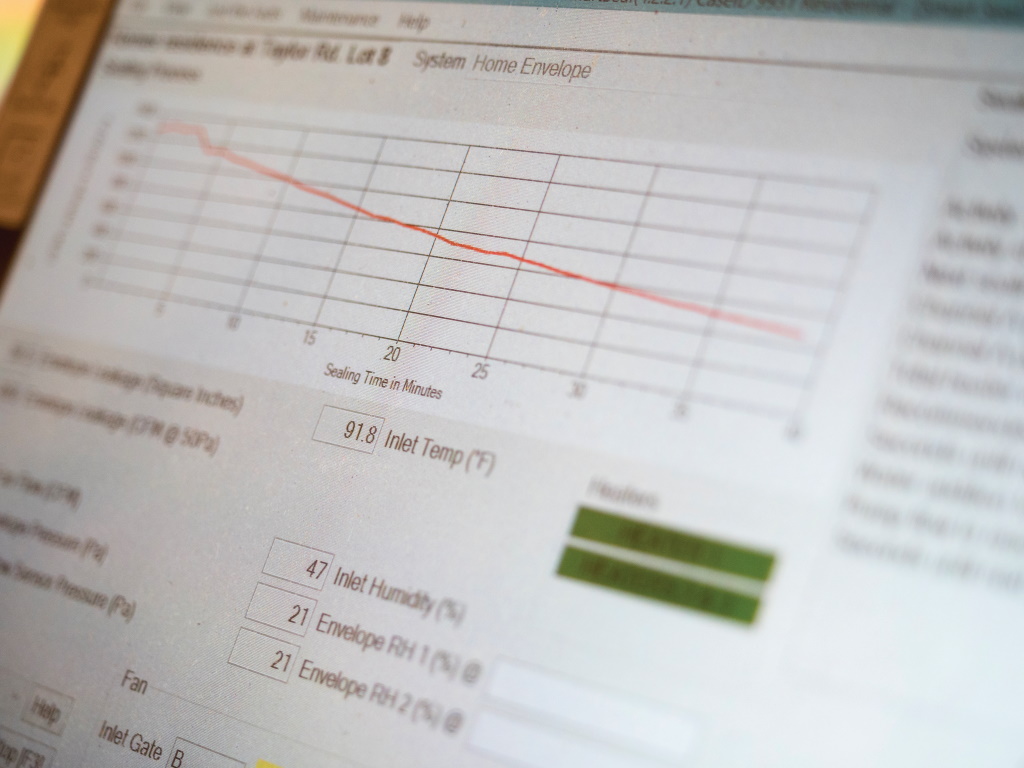

The system measures the envelope leakage in real time, enabling the system to dial in specific requirements for air leakage and guarantee the results.

The Sealant

AeroBarrier is a non-toxic, water-borne acrylic sealant designed for health.

Insulation used is third-party certified to have zero or ultra-low formaldehyde (less than 0.008 ppm)

The test determines the Surface Burning Characteristics of the material, specifically the flame spread and smoke developed indices when exposed to fire.

Following the fifty cycles of flexing and accelerated aging, simulating a 50 year period of service, Aerobarrier’s sealant showed no evidence of cracking, crazing, or spalling.

4 STEPS to Advanced Envelope Air Sealing

Step 1

Prep & Setup

Prep & Setup

Prep the area by covering any openings that won’t be sealed. This includes taping or covering any designed openings or finished horizontal surfaces within the space. Emitters are then set up throughout the area to be sealed.

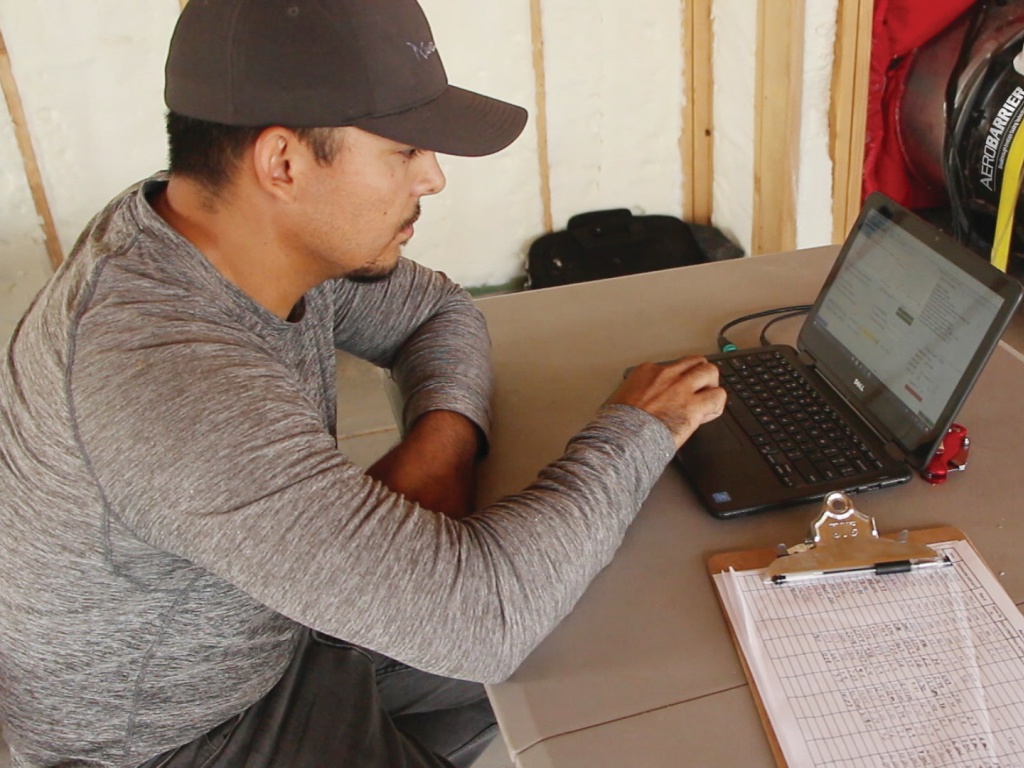

The equipment is then set up. This includes blower door, emitters, hoses, and the AeroBarrier machine.

Step 2

Pressurize & Apply

Pressurize & Apply

Using a blower door, the space is pressurized. After that, a computer controls the entire process including controlling the temperature, pressure, humidity, and distribution of sealant within the space during the process.

Step 3

Seal & Monitor

Seal & Monitor

With the AeroBarrier process you see results in real time. You have complete control over your desired level of air tightness and can achieve any level of tightness required. At the end of the process, a final blower door test is run to verify the sealing results. AeroBarrier then provides a Certificate of Completion that shows pre and post seal leakage.

Step 4

Clean Up

Clean Up

After the sealing is complete, work can resume in the space within 30 minutes. At that time, clean up of all equipment and removal of all tape and coverings can occur.

Residential

Affordable Airtightness

In residential applications, reduced envelope leakage means increased durability, reduced mechanical loads, improved energy efficiency, and more economical renewable energy options. More importantly, a tighter building envelope can help increase the comfort of a home and improve the overall indoor air quality within the home, leading to a better living environment for the homeowner.

Multi-Family

Code Compliance Made Easy

AeroBarrier is a perfect solution for compartmentalization and multi-family applications. Not only will a tighter building envelope help save energy, but it will also help stop moisture drive and reduce stack effect in the entire building. It will also help control sound and smell transfer, improve overall occupant comfort, and help mitigate pest movement which helps to enhance the environment in each unit.

Commercial

Fastest Path to Energy Savings

AeroBarrier is not only for residential applications. Aerosol sealing is proven to be extremely effective at sealing commercial spaces too. In commercial projects, AeroBarrier is able to reduce up to 80% of the building leakage. Using AeroBarrier in new or retrofit commercial applications improves the sealing effectiveness, reduces labor costs, and improves the consistency of installation.